Peculiar application of Citroën transaxle in Lotus Esprit

Approximately 6,074 Esprits were made with Citroen DS/SM transaxle and inboard disc brakes. Lotus 910 engine can be easily modified to deliver more power, but the transmission is the weak link. Citroen SM/DS gear box was used on all Lotus Esprit models from 1975 to 1988 MY.

![Image]()

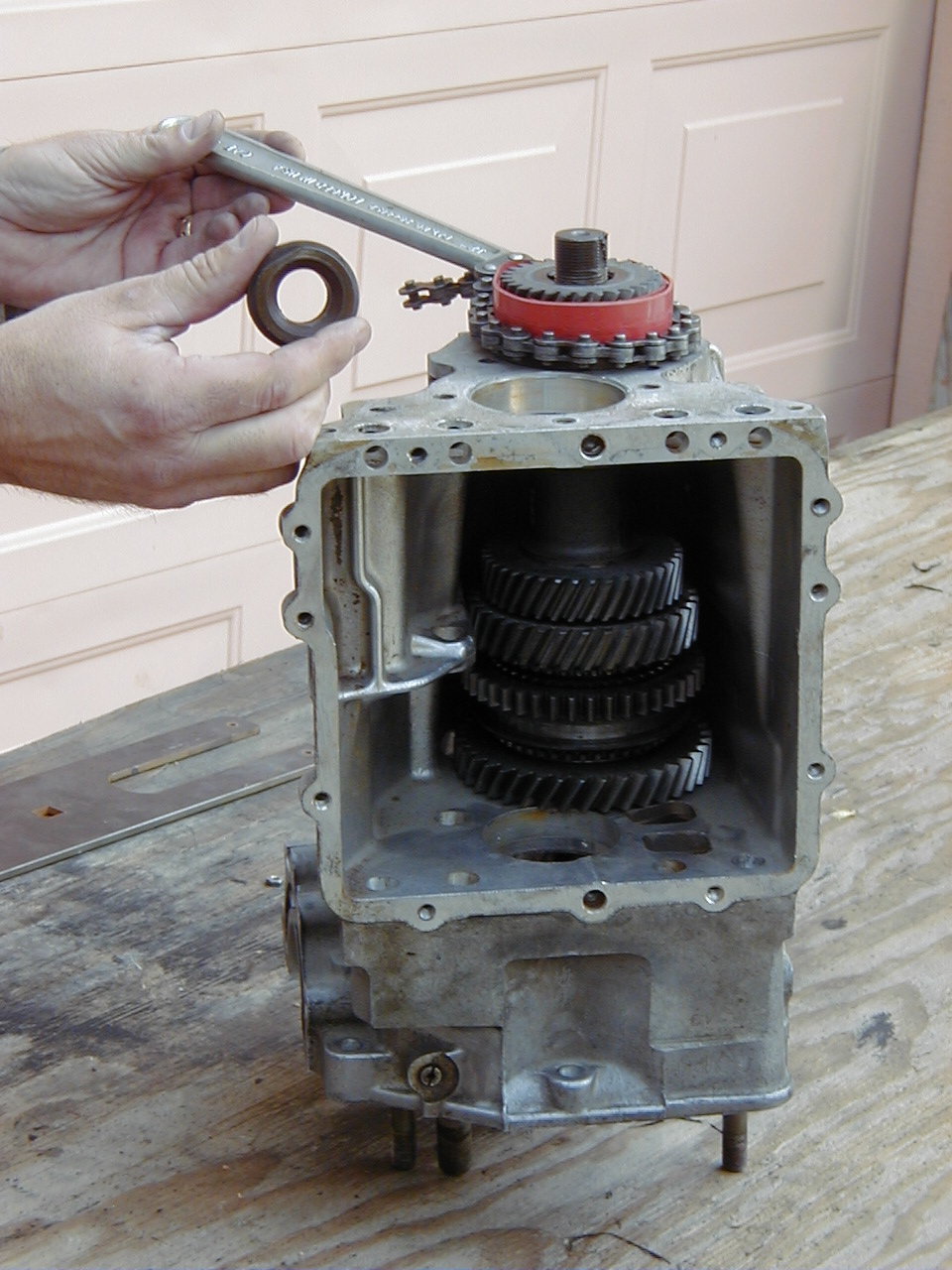

Citroën 5 speed gear box was designed in late 60-s for normally aspirated delivery vans with engines producing maximum 170 ft lbs of torque. On Esprits these gearboxes came in 2 versions, early on S1, S2, and starting with S3 Esprit in early 1984, C35 version.

It is important to distinguish early Esprit units (S1 & S2) from the later cars: The shift lever on the gearbox (fore/aft lever as opposed to the side/side cross-gate cable actuator) is on the left hand side on the early cars. The S3 and Turbo cars had a new Lotus specific gearbox top cover with the lever relocated to the right side. This moved the shift linkage to the engine intake side and away from the hot exhaust. Heat from the early cars exhaust system would cook the plastic bushings in the mechanical shift linkage in short order. The result would be very sloppy linkage after only limited exposure to the heat.

Citroën transaxle can handle Maserati Merak SS 217hp and much more with no problems. In spite of the same mid-ship engine layout, the transmission internally rotates in the correct direction, because the crown wheel was flipped to the other side (from DS/SM configuration).

![Image]()

Esprit CW

![Image]()

Maserati CW position

For 31 years, Dave Burnham races his Ice Racer Car using tuned 320 flywheel Hp Maserati engine, Citroen gear box, dual disc Tilton Clutch and aluminum flywheel .

![Image]()

Esprit engine rotates in the OPPOSITE direction than Maserati. Citroën transaxle was never designed to rotate in the "wrong" direction in conjunction with Turbo 910 engine.

Initially, Lotus used this tranny in N/A 160 Hp 907/ 912 powered Esprits, and that was a good match. But, later, when the 910 engine stepped up the power, it took the Citroen box beyond its capacity whilst rotating "in reverse" to its design intent.

Common sense called for a stronger Crown Wheel & Pinion (CWP) for this British Super-car, but at the time, there were no high performance options on the market and Lotus didn't want to spend any money.

If you avoid dumping the clutch at the stoplight and don't slam-shift thru the gears, then the Citroen transaxle is perfectly up to the stock 910 engine. Not much fun and everybody would think that your grandma sits behind the steering wheel, LOL.

And again, on Citroen DS/SM cars and vans, the gear box is positioned in front of the engine which makes the CWP design correct for driving car forward.

Esprit is equipped with the same box as DS/SM, but flipped around 180 deg and placed behind the mid-riff engine rotating in the opposite direction, which causes the internals rotating "backwards" (opposite to the design intent)!

Pinion is always trying to "escape", i.e. climb up the slope (coast side) of the crown wheel teeth exerting excessive loads on the pinion bearing, often resulting in casing cracks!

![Image]()

.

FYI: There is a very good, U.S. source for some of the gearbox parts: SM World, in the Valley on the north side of Los Angeles. The shop is owned by Jerry & Sylvia Hathaway, who are extremely competent and helpful. SM World is possibly the best Citroen SM repair and restoration facility, as recognized by the Citroen factory:

Citroen SM World

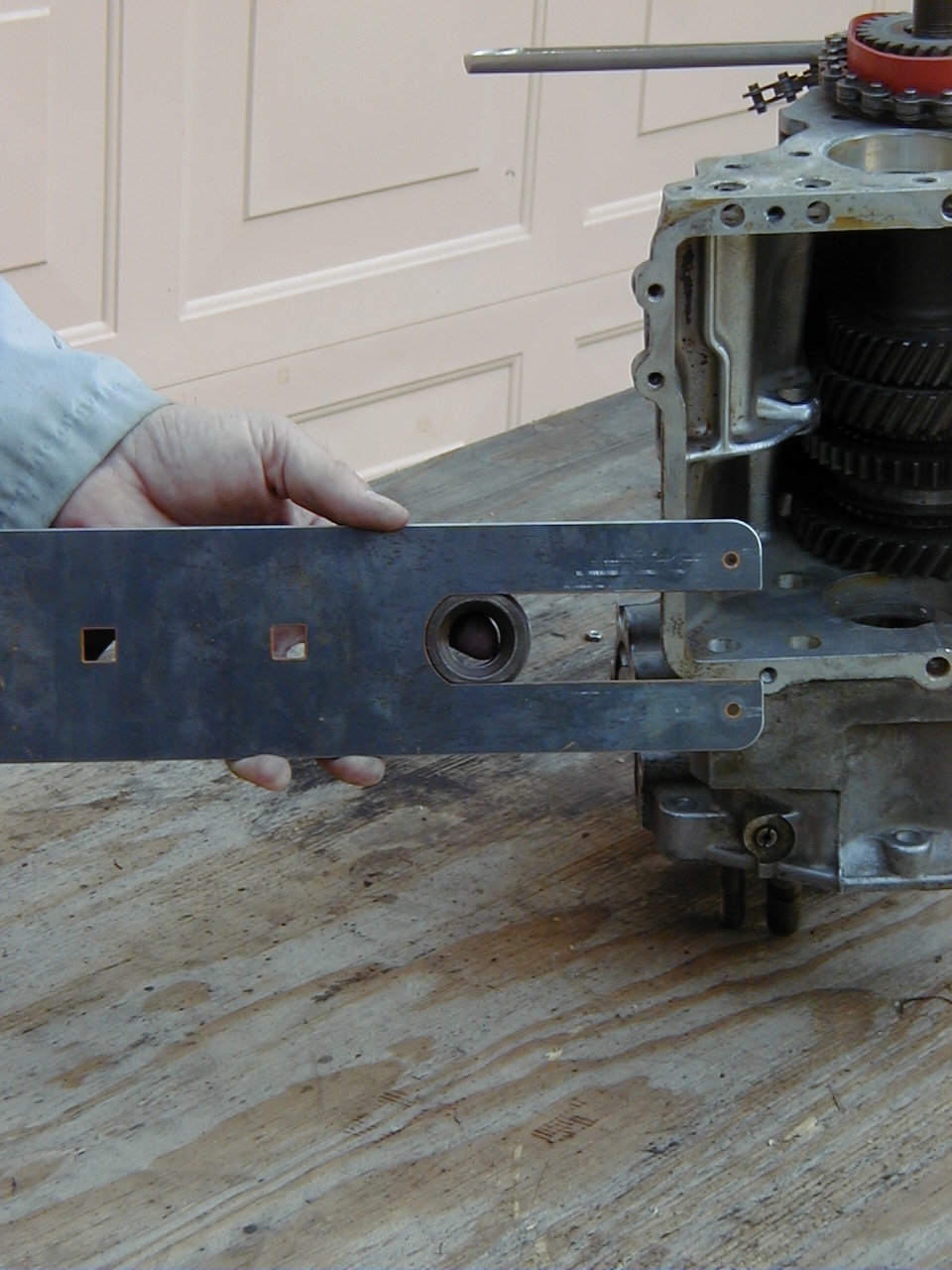

TRANSMISSION CITROEN SM, C35 REBUILD:

Lotus Turbo did a sort of "Zen Guide to Lotus Gearbox Rebuilds" which is here somewhere and might help...

www.thelotusforums.com

www.thelotusforums.com

www.thelotusforums.com

www.thelotusforums.com

Crown wheel and pinion are made of special hardened alloy steel and are matching pair with numbers.

They come from the factory in following ratios.

Standard 8/35 (4.375:1), passenger cars

Special 7/34 ( 4.857:1), vans and trucks

BUREL PROVENCE AUTOS ANCIENNES / DS23.com

~~~~~~~~~~~~~~~~~~~~

The weak points of C35 are:

Crown wheel carrier inferior quality bearings, input shaft circlip, weak crown wheel gear running "backwards", weak casing at the pinion bearing.

Like I said before, Citroen C35 gearbox was designed to run in front wheel drive Citroen DS/SM with engine at the front (behind the box). For Lotus configuration the whole gearbox was "flipped around" and placed behind the mid-ship engine, thus the CWP and all internals run "backwards"! Not the best situation!

Ideally, the pinion gear should rotate crown wheel on the drive side of the teeth. If however, the CW is driven on the coast side, strength of the gear set can be reduced by as much as ~30%.

Therefore, the CWP on Esprit is weak in forward drive and its strength is much better in overrun!

Similar problem has been discovered in Land Rover front differential, which got resolved very elegantly. http://www.kamdiffs.com/products-2/diff-ratio/

As it is mentioned in 2015 on KAM website, in the OEM front axle of Land Rover the gear set is running “backwards”, being driven on the coast side of the teeth rather than the driven side and as such, it is inherently weaker. Reverse cut gear set was required to remedy this problem!

Similar solution would benefit Esprit owners. See attached photo of KAM old web site, below.

Beefed up CWP with revised ratio and correct rotation would fix for 90% of the C35 problems. Cryogenic treatment and and REMS ISF Superfinsh would provide additional strength.

I decided to look in depth into this (overlooked for years!) Esprit CWP problem.

FYI:

In spiral bevel gears, any offset of the pinion from the crown wheel center line is hypoid, and the further off axis the greater the hypoid effect.

The Citroen and Renault UN-1 pinions are at their crown wheel's center line axis, so they are technically, spiral bevel gears, not hypoid.

FYI:

Here is what Tim Engel wrote about Citroen box:

910 engine has a lot of untapped power potential, and you can easily create a monster that doesn't play well with others... i.e. the 910 will beat up on the Citroen box.

In normal use, the 1-2 synchros take a beating because they generally get used more often and harder. 5th synchros wear because there's a big step between 4th & 5th, and the synchro is asked to do a lot of work with each shift (apply pressure, don't rush it). Replace synchros whenever you're in there just to keep them fresh, but there isn't an optional Porsche-style synchro system available. It's typical of how French transmissions shift... "They all do that, sir".

If you wish to shift more quickly, install a Porsche transaxle and tell us all how you did it. There is no "standard" swap we can tell you about. The baulk-ring style synchro shifts at it's own pace and doesn't like to be slam-shifted. Apply pressure and wait for it to happen. If you force it, you'll just frustrate yourself and/or grind up precious metal. There are often message threads on this list that go something like... Graunch, graunch, graunch...

"Why does my transaxle grind when I shift gears?" Usually, it comes out in further conversation that the owner wants to shift FASTER. Well, maybe it is possible the synchros are actually old and worn out. But more often than not, it's because somebody is playing boy-racer, and trying to speed-shift baulk-ring synchros that, by design, don't like fast... and without having a clue how to match rpm-s. Slow down and shift the way the Citroen (Renault) is supposed to be shifted, or learn how to drive. But don't be blaming or flogging the gearbox.

BTW, of the two Esprit trans-axles, the Citroen responds better to rpm matching than the UN1... or Europa. I can shift up and down from 1st thru 4th without the clutch, but 5th is a little more challenging. The Europas I've owned would never put up with that, and the Esprit Renault UN1 doesn't like it either. I'm not recommending shifting without the clutch, just suggesting that the Citroen's synchros do appreciate a little help from a driver who knows how to match rpms, and it would be a good thing for you to learn... as opposed to "fixing" the gearbox.

Harry Martens and JAE both offer (do... did... ??) a Quaife limited slip differential for the Citroen. The claim is that it's the solution for handling more power.

Of course, the limited slip will help put the added power to the road. But I get lost in the claims I thought I heard about it protecting other internal parts, like the CWP. That's where I get lost. If the power goes to one wheel, and the one tire breaks traction and spins, that's your safety valve. Loss of traction at one wheel happens at a torque level the CWP can handle, and adding more power after that just spins the tire faster without putting more power to the road.

If you install a limited slip differential, then power goes to both rear wheels pretty much equally. Both rear tires are sharing the load, and it takes a lot more torque to break loose and spin two tires instead of one.

That puts more load on the CWP, not less. I believe the premise of the claims is that if the one driving wheel hits a slick spot on the road and spins-up, then gets good rip on a clean spot (sandy to clean, or wet to dry), then all the spinning energy slams into the CWP when the tires finally bite.

That shock-energy is what kills the CWP, and the limited slip prevents (well, minimizes) the possibility of wildly spinning the tires with stock power. However, adding lots of horsepower can then spin both rear tires together pretty much at will. Then when both tires do bite, there will be even more violent inertia slamming into the CWP. The stock CWP didn't get any stronger when the limited slip diff was installed, it can only support so much torque and shock, and shock loads will strip off teeth. That gets us back to the repeating theme of all this... the Citroen transaxle was never originally designed to deal with the 910's power potential, there are no aftermarket hotrod parts available for it, and you need to deal with that. Or trade up to an SE.

Regards,

Tim Engel

Approximately 6,074 Esprits were made with Citroen DS/SM transaxle and inboard disc brakes. Lotus 910 engine can be easily modified to deliver more power, but the transmission is the weak link. Citroen SM/DS gear box was used on all Lotus Esprit models from 1975 to 1988 MY.

Citroën 5 speed gear box was designed in late 60-s for normally aspirated delivery vans with engines producing maximum 170 ft lbs of torque. On Esprits these gearboxes came in 2 versions, early on S1, S2, and starting with S3 Esprit in early 1984, C35 version.

It is important to distinguish early Esprit units (S1 & S2) from the later cars: The shift lever on the gearbox (fore/aft lever as opposed to the side/side cross-gate cable actuator) is on the left hand side on the early cars. The S3 and Turbo cars had a new Lotus specific gearbox top cover with the lever relocated to the right side. This moved the shift linkage to the engine intake side and away from the hot exhaust. Heat from the early cars exhaust system would cook the plastic bushings in the mechanical shift linkage in short order. The result would be very sloppy linkage after only limited exposure to the heat.

Citroën transaxle can handle Maserati Merak SS 217hp and much more with no problems. In spite of the same mid-ship engine layout, the transmission internally rotates in the correct direction, because the crown wheel was flipped to the other side (from DS/SM configuration).

Esprit CW

Maserati CW position

For 31 years, Dave Burnham races his Ice Racer Car using tuned 320 flywheel Hp Maserati engine, Citroen gear box, dual disc Tilton Clutch and aluminum flywheel .

Esprit engine rotates in the OPPOSITE direction than Maserati. Citroën transaxle was never designed to rotate in the "wrong" direction in conjunction with Turbo 910 engine.

Initially, Lotus used this tranny in N/A 160 Hp 907/ 912 powered Esprits, and that was a good match. But, later, when the 910 engine stepped up the power, it took the Citroen box beyond its capacity whilst rotating "in reverse" to its design intent.

Common sense called for a stronger Crown Wheel & Pinion (CWP) for this British Super-car, but at the time, there were no high performance options on the market and Lotus didn't want to spend any money.

If you avoid dumping the clutch at the stoplight and don't slam-shift thru the gears, then the Citroen transaxle is perfectly up to the stock 910 engine. Not much fun and everybody would think that your grandma sits behind the steering wheel, LOL.

And again, on Citroen DS/SM cars and vans, the gear box is positioned in front of the engine which makes the CWP design correct for driving car forward.

Esprit is equipped with the same box as DS/SM, but flipped around 180 deg and placed behind the mid-riff engine rotating in the opposite direction, which causes the internals rotating "backwards" (opposite to the design intent)!

Pinion is always trying to "escape", i.e. climb up the slope (coast side) of the crown wheel teeth exerting excessive loads on the pinion bearing, often resulting in casing cracks!

.

FYI: There is a very good, U.S. source for some of the gearbox parts: SM World, in the Valley on the north side of Los Angeles. The shop is owned by Jerry & Sylvia Hathaway, who are extremely competent and helpful. SM World is possibly the best Citroen SM repair and restoration facility, as recognized by the Citroen factory:

Citroen SM World

TRANSMISSION CITROEN SM, C35 REBUILD:

Lotus Turbo did a sort of "Zen Guide to Lotus Gearbox Rebuilds" which is here somewhere and might help...

gearbox rebuild

HI guys, As you know I'm restoring my lotus esprit S2.2. I was planning in the past to send my gearbox "like it is" to Harry Martens for a rebuild.... But...my interest in the mechanical and technical parts of my "babe" is really so strong that I have take the MAD and hard decision to do the job ...

www.thelotusforums.com

www.thelotusforums.com

S2 Gearbox Stripdown

Hi All, Decided to rebuild the Citroen transaxle in my 79 Federal S2. I initially planned to replace all 8 bearings and all synchros but after seeing a price quote for all these parts I decided to replace only those items that are worn (I will replace the carrier bearings regardless). I've got th...

www.thelotusforums.com

www.thelotusforums.com

Crown wheel and pinion are made of special hardened alloy steel and are matching pair with numbers.

They come from the factory in following ratios.

Standard 8/35 (4.375:1), passenger cars

Special 7/34 ( 4.857:1), vans and trucks

BUREL PROVENCE AUTOS ANCIENNES / DS23.com

~~~~~~~~~~~~~~~~~~~~

The weak points of C35 are:

Crown wheel carrier inferior quality bearings, input shaft circlip, weak crown wheel gear running "backwards", weak casing at the pinion bearing.

Like I said before, Citroen C35 gearbox was designed to run in front wheel drive Citroen DS/SM with engine at the front (behind the box). For Lotus configuration the whole gearbox was "flipped around" and placed behind the mid-ship engine, thus the CWP and all internals run "backwards"! Not the best situation!

Ideally, the pinion gear should rotate crown wheel on the drive side of the teeth. If however, the CW is driven on the coast side, strength of the gear set can be reduced by as much as ~30%.

Therefore, the CWP on Esprit is weak in forward drive and its strength is much better in overrun!

Similar problem has been discovered in Land Rover front differential, which got resolved very elegantly. http://www.kamdiffs.com/products-2/diff-ratio/

As it is mentioned in 2015 on KAM website, in the OEM front axle of Land Rover the gear set is running “backwards”, being driven on the coast side of the teeth rather than the driven side and as such, it is inherently weaker. Reverse cut gear set was required to remedy this problem!

Similar solution would benefit Esprit owners. See attached photo of KAM old web site, below.

Beefed up CWP with revised ratio and correct rotation would fix for 90% of the C35 problems. Cryogenic treatment and and REMS ISF Superfinsh would provide additional strength.

I decided to look in depth into this (overlooked for years!) Esprit CWP problem.

FYI:

In spiral bevel gears, any offset of the pinion from the crown wheel center line is hypoid, and the further off axis the greater the hypoid effect.

The Citroen and Renault UN-1 pinions are at their crown wheel's center line axis, so they are technically, spiral bevel gears, not hypoid.

FYI:

Here is what Tim Engel wrote about Citroen box:

910 engine has a lot of untapped power potential, and you can easily create a monster that doesn't play well with others... i.e. the 910 will beat up on the Citroen box.

In normal use, the 1-2 synchros take a beating because they generally get used more often and harder. 5th synchros wear because there's a big step between 4th & 5th, and the synchro is asked to do a lot of work with each shift (apply pressure, don't rush it). Replace synchros whenever you're in there just to keep them fresh, but there isn't an optional Porsche-style synchro system available. It's typical of how French transmissions shift... "They all do that, sir".

If you wish to shift more quickly, install a Porsche transaxle and tell us all how you did it. There is no "standard" swap we can tell you about. The baulk-ring style synchro shifts at it's own pace and doesn't like to be slam-shifted. Apply pressure and wait for it to happen. If you force it, you'll just frustrate yourself and/or grind up precious metal. There are often message threads on this list that go something like... Graunch, graunch, graunch...

"Why does my transaxle grind when I shift gears?" Usually, it comes out in further conversation that the owner wants to shift FASTER. Well, maybe it is possible the synchros are actually old and worn out. But more often than not, it's because somebody is playing boy-racer, and trying to speed-shift baulk-ring synchros that, by design, don't like fast... and without having a clue how to match rpm-s. Slow down and shift the way the Citroen (Renault) is supposed to be shifted, or learn how to drive. But don't be blaming or flogging the gearbox.

BTW, of the two Esprit trans-axles, the Citroen responds better to rpm matching than the UN1... or Europa. I can shift up and down from 1st thru 4th without the clutch, but 5th is a little more challenging. The Europas I've owned would never put up with that, and the Esprit Renault UN1 doesn't like it either. I'm not recommending shifting without the clutch, just suggesting that the Citroen's synchros do appreciate a little help from a driver who knows how to match rpms, and it would be a good thing for you to learn... as opposed to "fixing" the gearbox.

Harry Martens and JAE both offer (do... did... ??) a Quaife limited slip differential for the Citroen. The claim is that it's the solution for handling more power.

Of course, the limited slip will help put the added power to the road. But I get lost in the claims I thought I heard about it protecting other internal parts, like the CWP. That's where I get lost. If the power goes to one wheel, and the one tire breaks traction and spins, that's your safety valve. Loss of traction at one wheel happens at a torque level the CWP can handle, and adding more power after that just spins the tire faster without putting more power to the road.

If you install a limited slip differential, then power goes to both rear wheels pretty much equally. Both rear tires are sharing the load, and it takes a lot more torque to break loose and spin two tires instead of one.

That puts more load on the CWP, not less. I believe the premise of the claims is that if the one driving wheel hits a slick spot on the road and spins-up, then gets good rip on a clean spot (sandy to clean, or wet to dry), then all the spinning energy slams into the CWP when the tires finally bite.

That shock-energy is what kills the CWP, and the limited slip prevents (well, minimizes) the possibility of wildly spinning the tires with stock power. However, adding lots of horsepower can then spin both rear tires together pretty much at will. Then when both tires do bite, there will be even more violent inertia slamming into the CWP. The stock CWP didn't get any stronger when the limited slip diff was installed, it can only support so much torque and shock, and shock loads will strip off teeth. That gets us back to the repeating theme of all this... the Citroen transaxle was never originally designed to deal with the 910's power potential, there are no aftermarket hotrod parts available for it, and you need to deal with that. Or trade up to an SE.

Regards,

Tim Engel